adago for Life Science Industries

We simulate and optimize complex life science supply networks, connecting CMOs, production, and business sites to navigate scale-up challenges and turn volatility into resilience.

The Three Achilles' Heels of Life Science Supply Chains

Multi-Scale Whiplash

Juggling small-batch clinical precision with commercial-scale efficiency creates friction.

Transitioning from low-volume, high-variability trial materials to mass production risks underutilized equipment, rushed tech transfers, or costly overstocking.

Ecosystem Blindspots

Disjointed data across CDMOs, suppliers, and internal ERPs creates 'blackout zones'.

Delays at third-party sites go undetected until they disrupt batches, while inventory mismatches plague outsourced production stages.

Perishable Resilience

Balancing shelf-life constraints with volatile demand requires surgical precision.

Overstocking risks waste; understocking risks stockouts. Add cold-chain fragility and sudden regulatory approvals.

How adago Transforms Life Science Operations

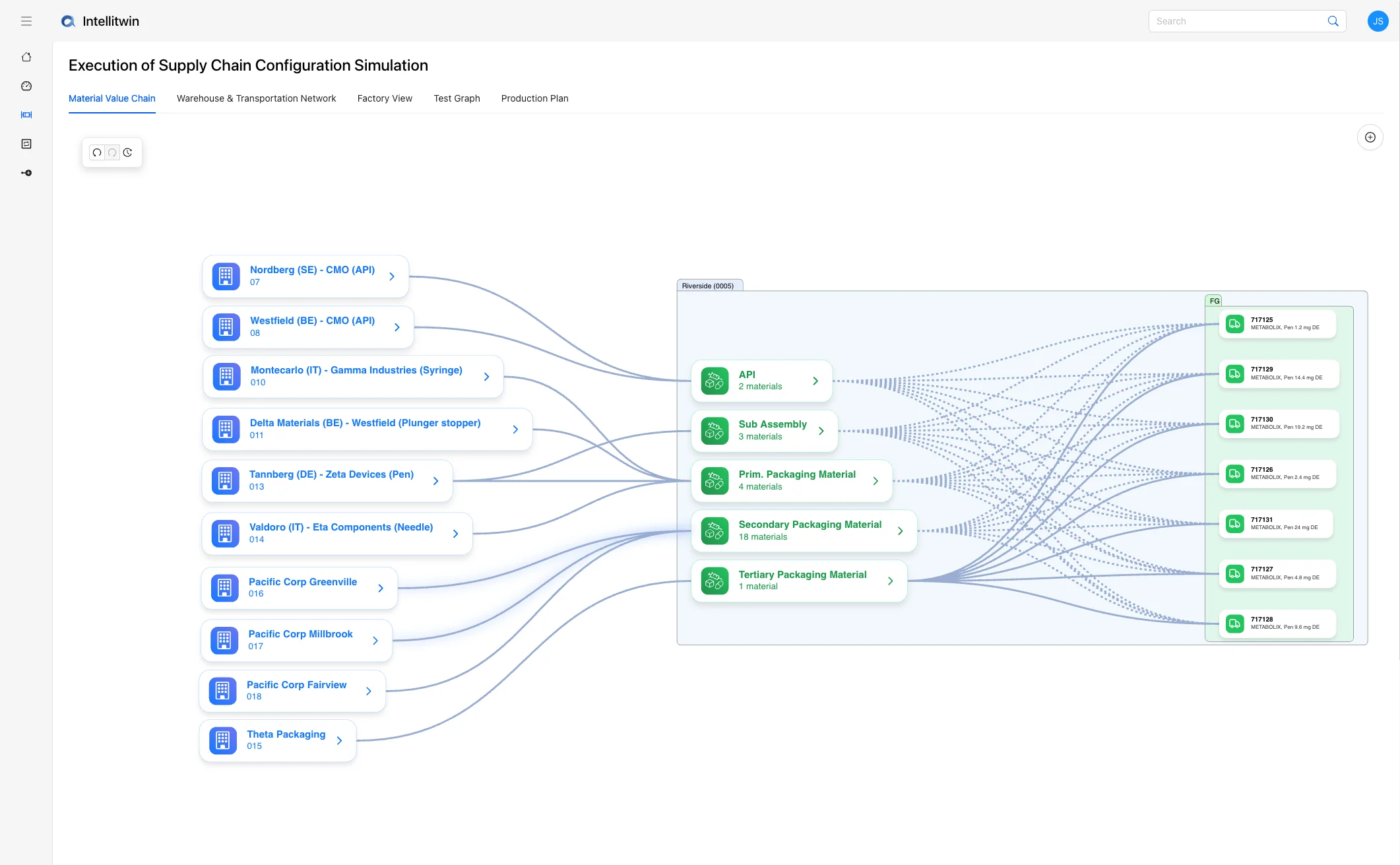

End-to-end Visualization

Achieve end-to-end visibility from production to logistics, making supply chain complexity and risks easier to understand and address.

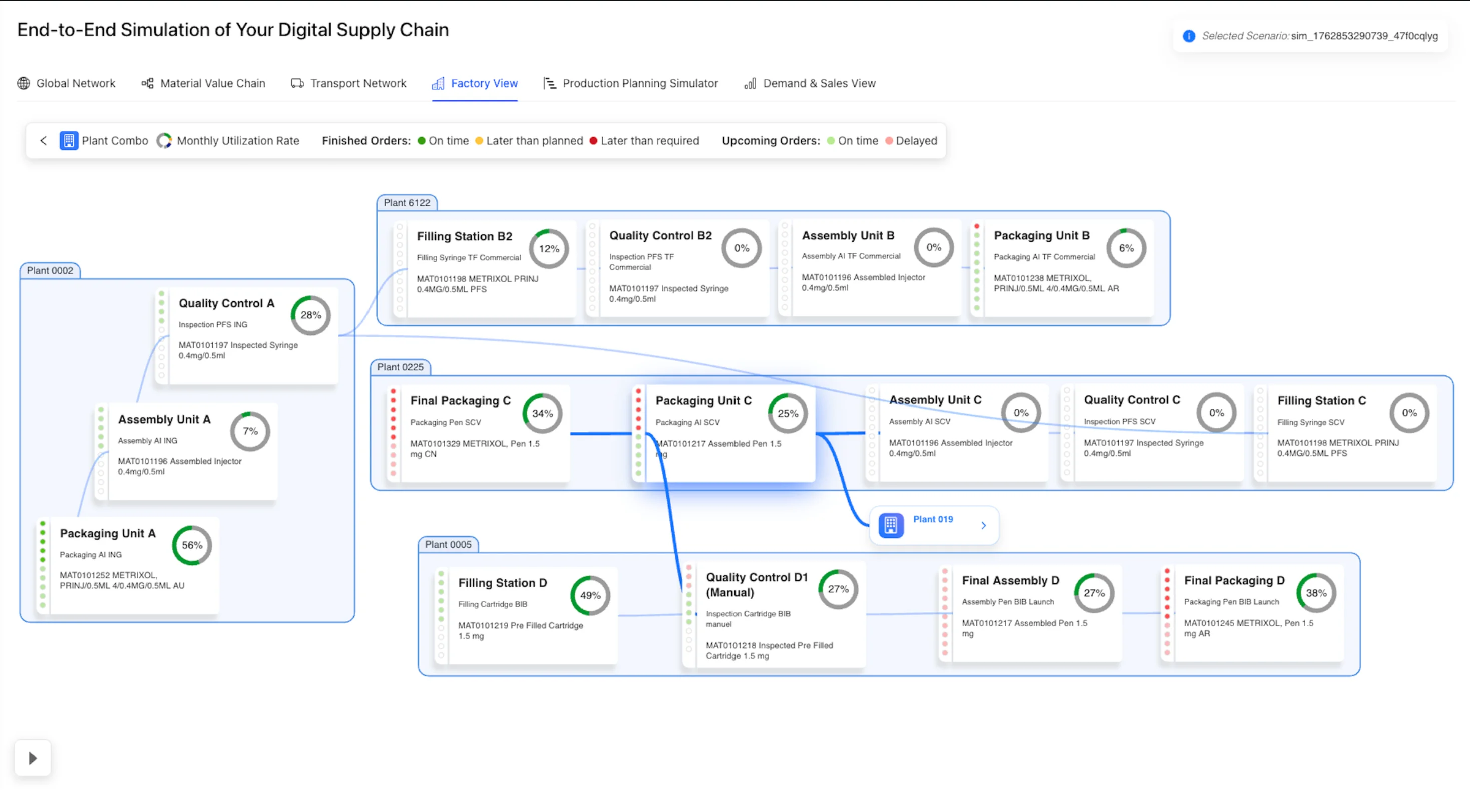

Scalable Production Simulations

Test different production scenarios, optimize resource allocation, and scale operations dynamically to meet market demands.

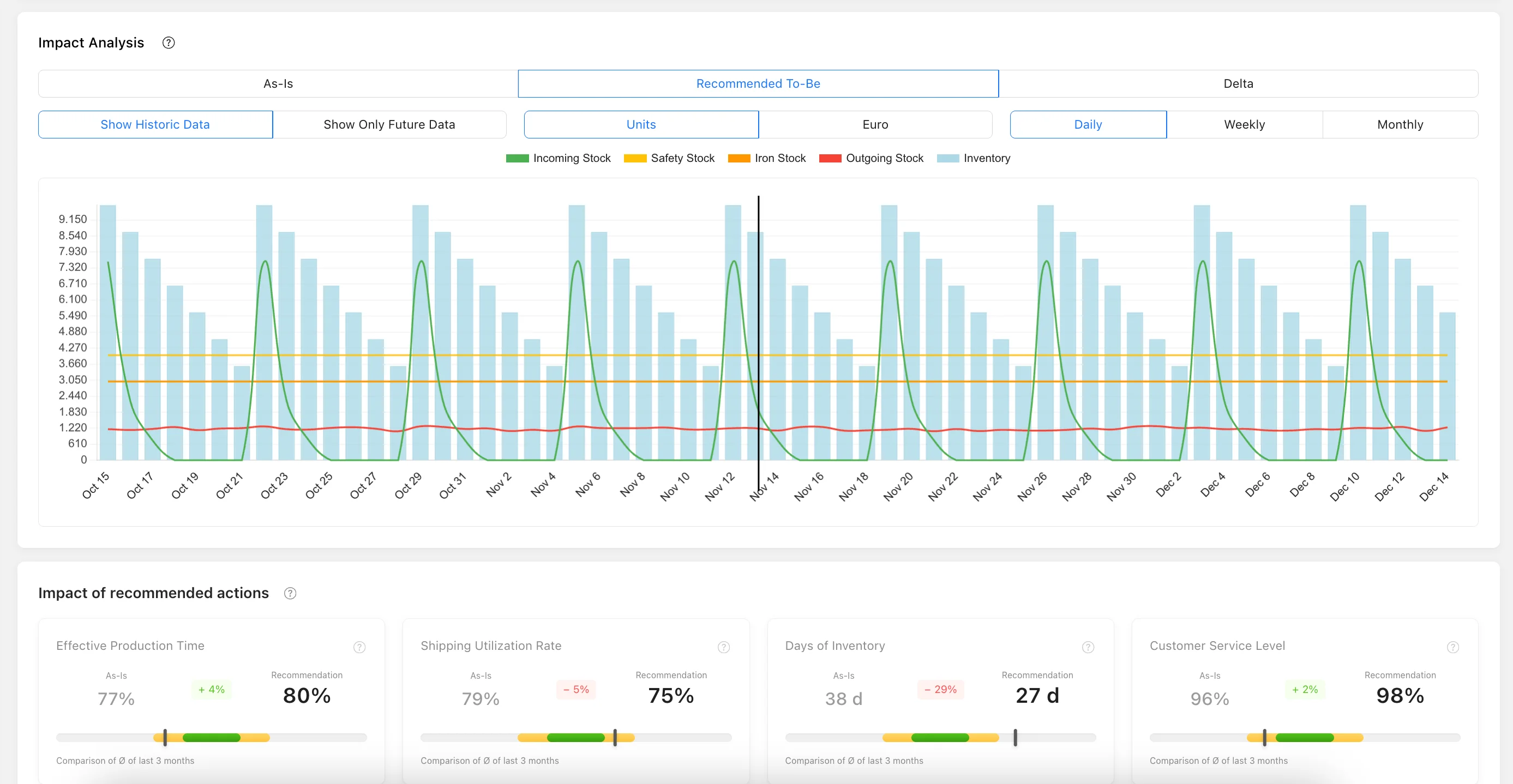

Inventory Optimization

Dynamically adjust stock levels based on real-time data and predictive analytics to maintain the right balance between supply and demand.

6 Ways adago Delivers Life Science Resilience

Cold Chain Armor for Biologics

Simulate freezer farm outages, transit delays, or power grid failures for mRNA vaccines and CAR-T therapies.

Clinical Trial Demand Precision

Predict erratic enrollment spikes with AI-driven simulations for optimized procurement.

Dual-Sourcing Without Bloat

Model geopolitical shocks or supplier bankruptcies for high-risk materials optimization.

Regulatory Batch Risk Mitigation

Simulate QA/QC bottlenecks or raw material deviations that delay batch releases.

Personalized Medicine Scalability

Optimize small-batch production for gene therapies and autologous treatments.

Pandemic-Proof Scale-Up

Stress-test rapid mRNA vaccine production scale-up with comprehensive modeling.

Moritz Kern

CEO

Ready to Transform Your Supply Chain?

Whether you're ready to request a demo or simply want to explore how our solution can benefit your business, we'd love to connect!

Get in Touch

Fill out the form below and we'll get back to you within 24 hours.