What is Agentic AI?

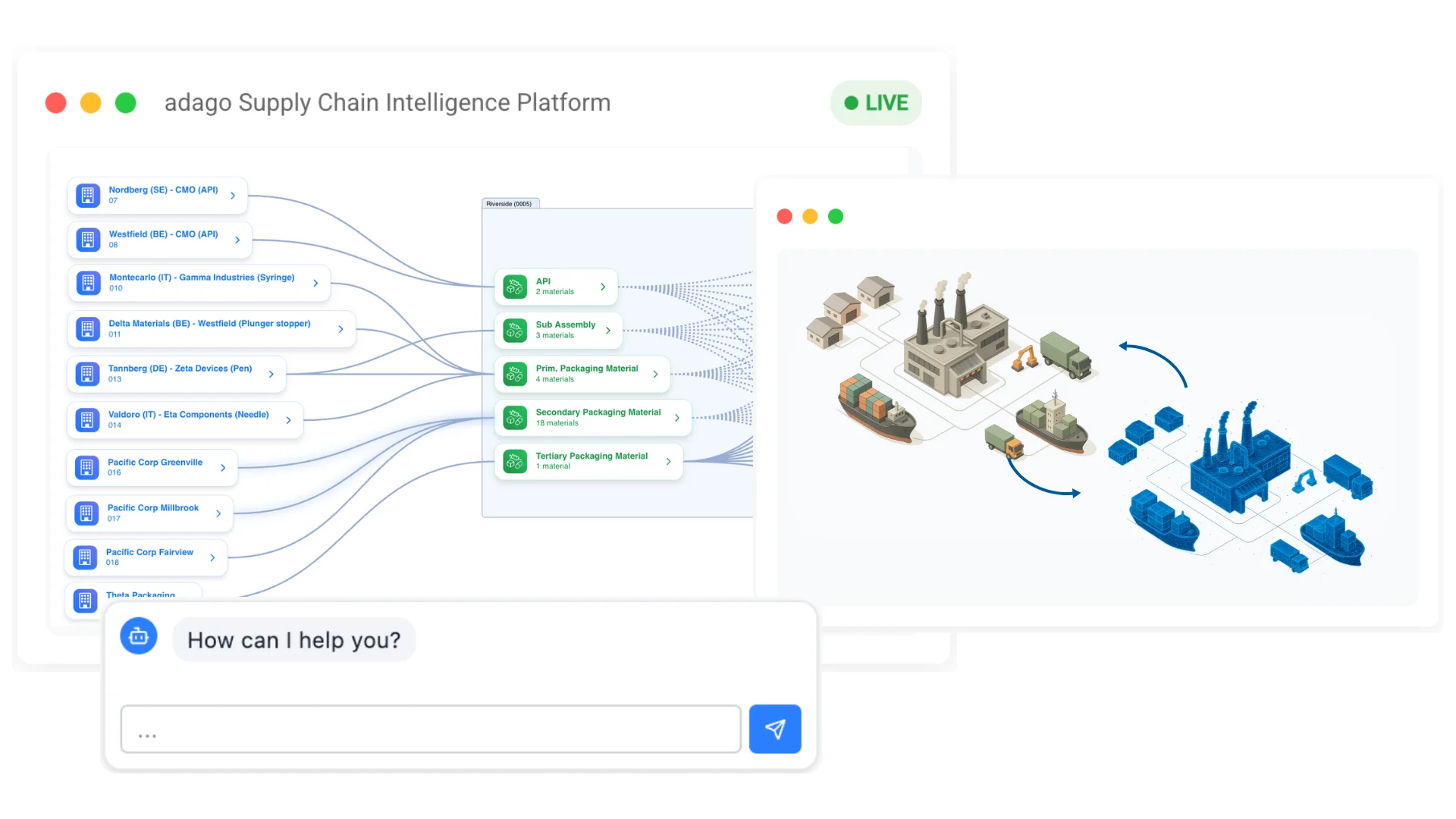

Our Agentic AI combines intelligent conversation interfaces with powerful background simulation engines, creating autonomous agents that continuously learn and optimize your supply chain operations.

User Interaction

AI Simulation Engine

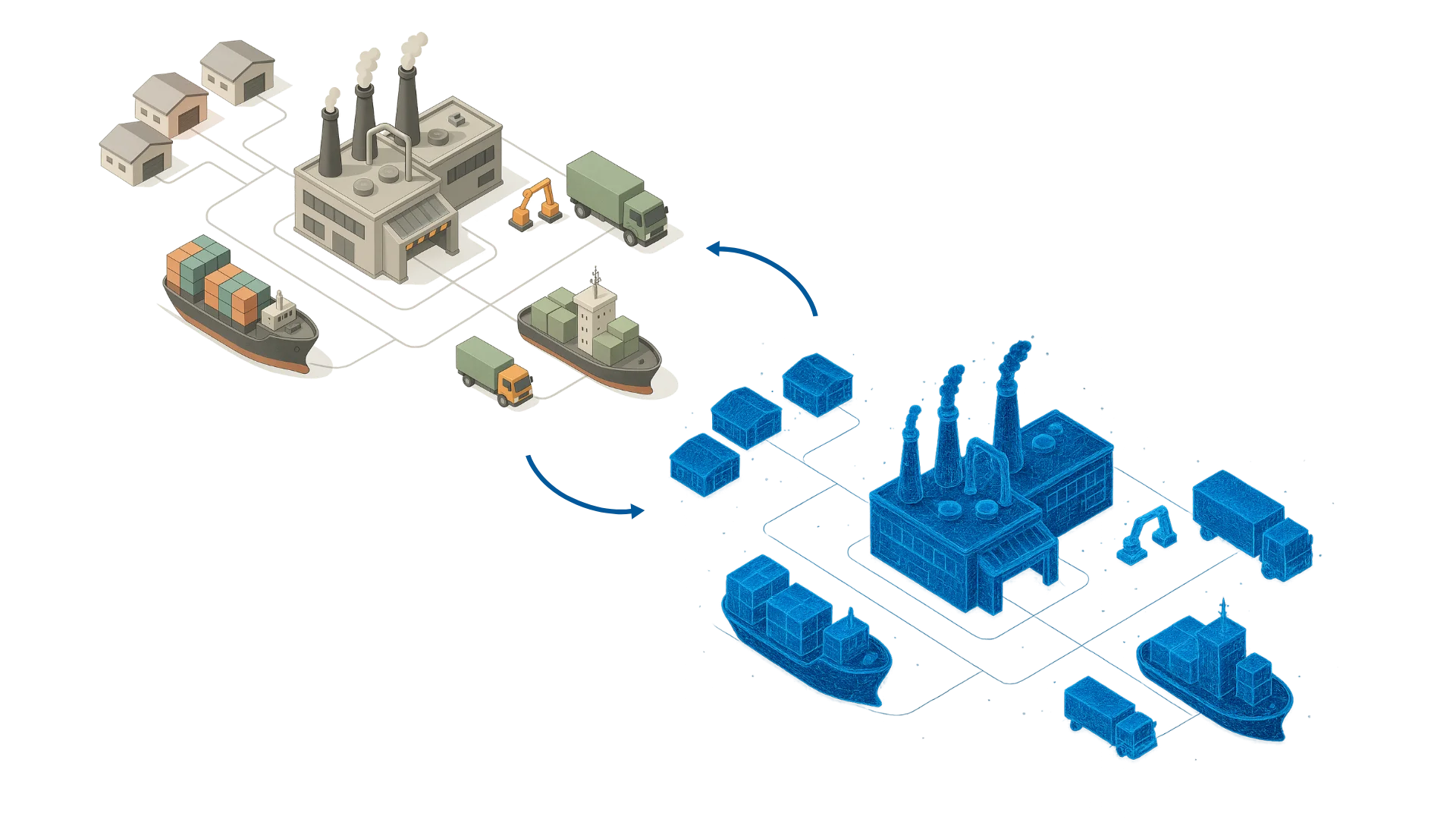

Your Supply Chain's Digital Mirror

Our Digital Twin creates a real-time, interactive replica of your entire supply chain ecosystem. Every supplier, facility, process, and connection is precisely modeled to enable perfect simulation and optimization scenarios.

Complete Network Modeling

Map every node, connection, and dependency across your entire supply network with real-time data synchronization.

Multi-Layer Analysis

Analyze operations from strategic planning down to individual SKU movements across multiple time horizons.

Real-time Calibration

Continuously calibrate the digital twin with live operational data for maximum accuracy and relevance.

Scenario Accuracy

Predict outcomes with industry-leading precision

Cost Reduction

Average operational cost savings achieved

Continuous Monitoring

Real-time visibility across all operations

Faster Decisions

Accelerated strategic planning cycles

Results and benefits may vary depending on individual circumstances and configurations.

Connect Your Existing Systems

adago IntelliTwin integrates seamlessly with your current infrastructure, connecting ERP systems, data platforms, and analytics tools to create a unified, intelligent supply chain ecosystem.

Three-Layer Integration Architecture

ERP Foundation Layer

Our platform connects to any modern ERP system, including but not limited to SAP S/4HANA, SAP ECC, Oracle, and other enterprise solutions. Real-time data synchronization ensures your digital twin stays current.

Data Platform Layer

Leverage your existing data infrastructure including cloud platforms and data warehouses. Scale processing power and storage as needed.

IntelliTwin Intelligence Layer

Our AI-powered digital twin sits on top, providing intelligent analysis, predictive insights, and optimization recommendations across your entire supply chain.

adago IntelliTwin

AI-Powered Supply Chain Intelligence

Data Platforms

ERP Systems

Plug & Play

No complex system overhauls. Connect to existing infrastructure with minimal disruption.

Enterprise Security

Bank-level encryption and compliance with SOC 2, GDPR, and industry standards.

Real-time Sync

Live data synchronization ensures your digital twin reflects current operations.

Discover Our Solutions

adago provides complete transparency along with powerful simulation and optimization capabilities. Explore our use cases and discover how our AI platform transforms every aspect of your supply chain operations.

Our Platform

Click to explore each solution in detail

Material Value Chain

Full Transparency

Factory Simulator

Simulating Resources

Production Simulator

Efficiency Optimization

Safety Stock Optimizer

Predictive Accuracy

EOQ Optimizer

Efficiency Optimization

Demand & Sales Simulator

Self-Learning Systems

Transportation Simulator

Analyse Logistics

Scenario Hub

What-If Analysis

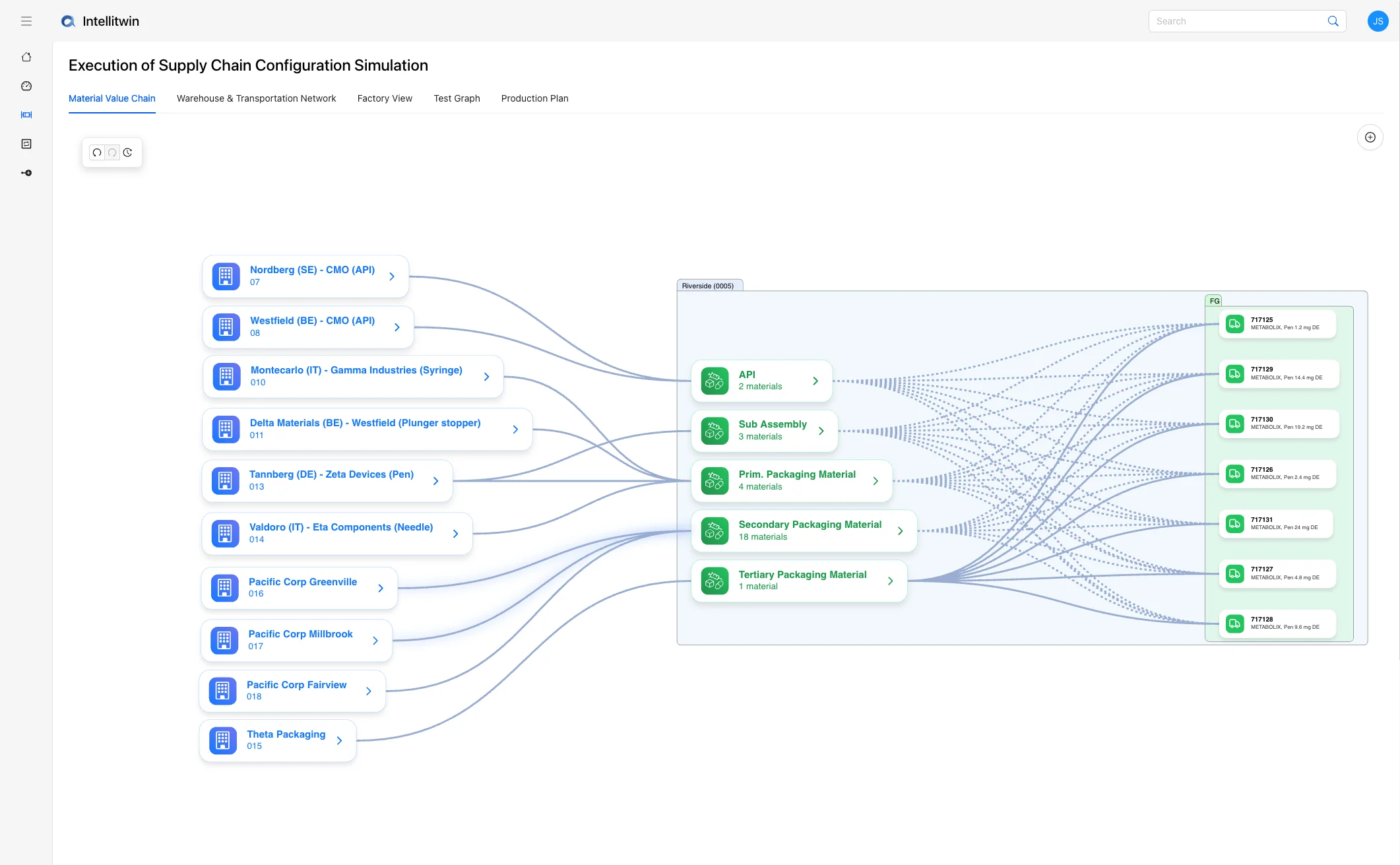

Material Value Chain

Gain full transparency of your entire supply chain through End-to-End Visualization - from API to Finished Goods.

Our Platform

Click on a card to view details

Material Value Chain

Full Transparency

Factory Simulator

Simulating Resources

Production Simulator

Efficiency Optimization

Safety Stock Optimizer

Predictive Accuracy

EOQ Optimizer

Efficiency Optimization

Demand & Sales Simulator

Self-Learning Systems

Transportation Simulator

Analyse Logistics

Scenario Hub

What-If Analysis

Moritz Kern

CEO

Ready to Transform Your Supply Chain?

Whether you're ready to request a demo or simply want to explore how our solution can benefit your business, we'd love to connect!

Get in Touch

Fill out the form below and we'll get back to you within 24 hours.